K Factor Formula

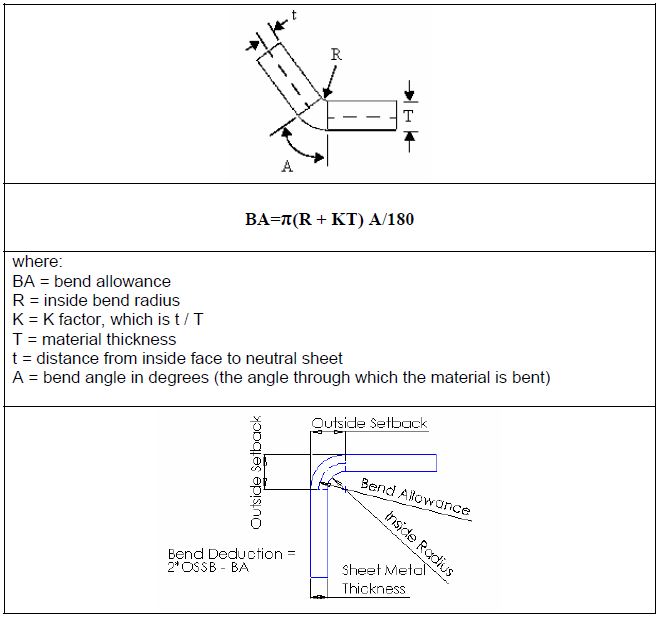

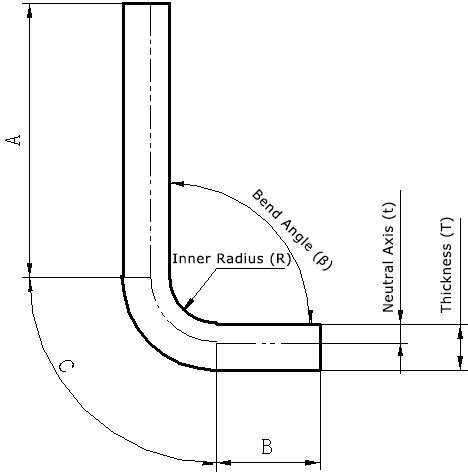

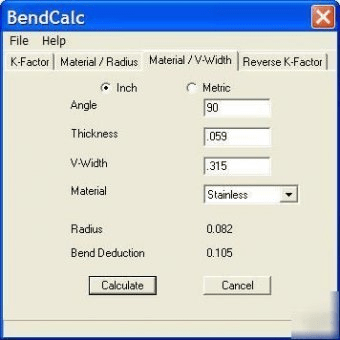

Then input the bend angle to get the arc length bend allowance and bend deduction.

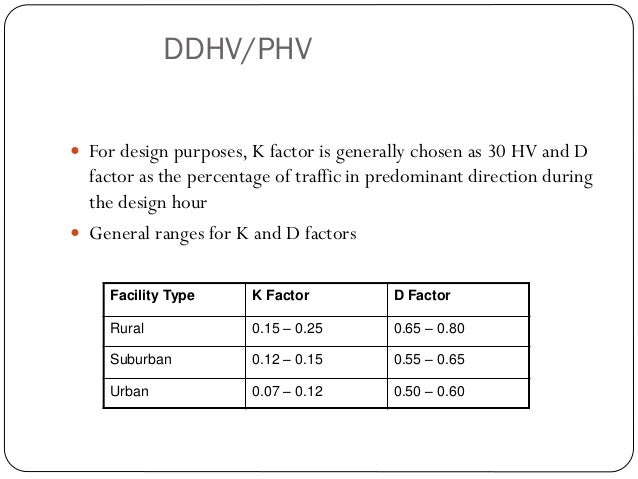

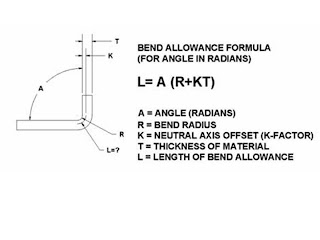

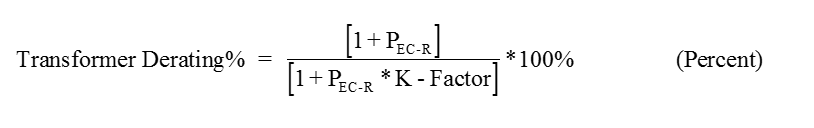

K factor formula. All other values are known to the user. The k factor is used to calculate flat patterns because it is directly related to how much material is stretched during the bend. The axial design of turbine flow meter is inherently linear within a known turndown range typically 151 based on velocity of the measured fluid.

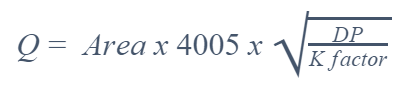

In above bend allowance formula except sheet metal k factor and bend allowance values. This formula uses a k factor of 0446. K factor aeronautics the number of pulses expected for every one volumetric unit of fluid passing through a given flow meter k factor centrifugation relative pelleting efficiency of a given centrifuge rotor k factor crude oil refining a system for classifying crude oil k factor fire protection formula used to calculate the discharge rate from a fire.

Then input leg length a and b to get the flat size of the sheet. The device has unmatched capability of precise and repeatable k factor generation based on the turning of the balanced rotor and the subsequently generated frequency pulse signal via the magnetic coil assembly providing. To know in detail about the experimental way of calculating k factor click to this link.

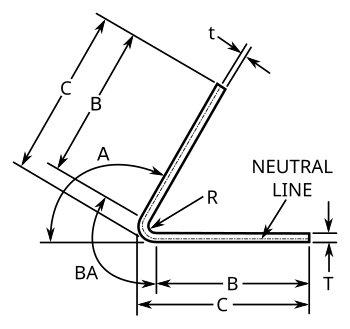

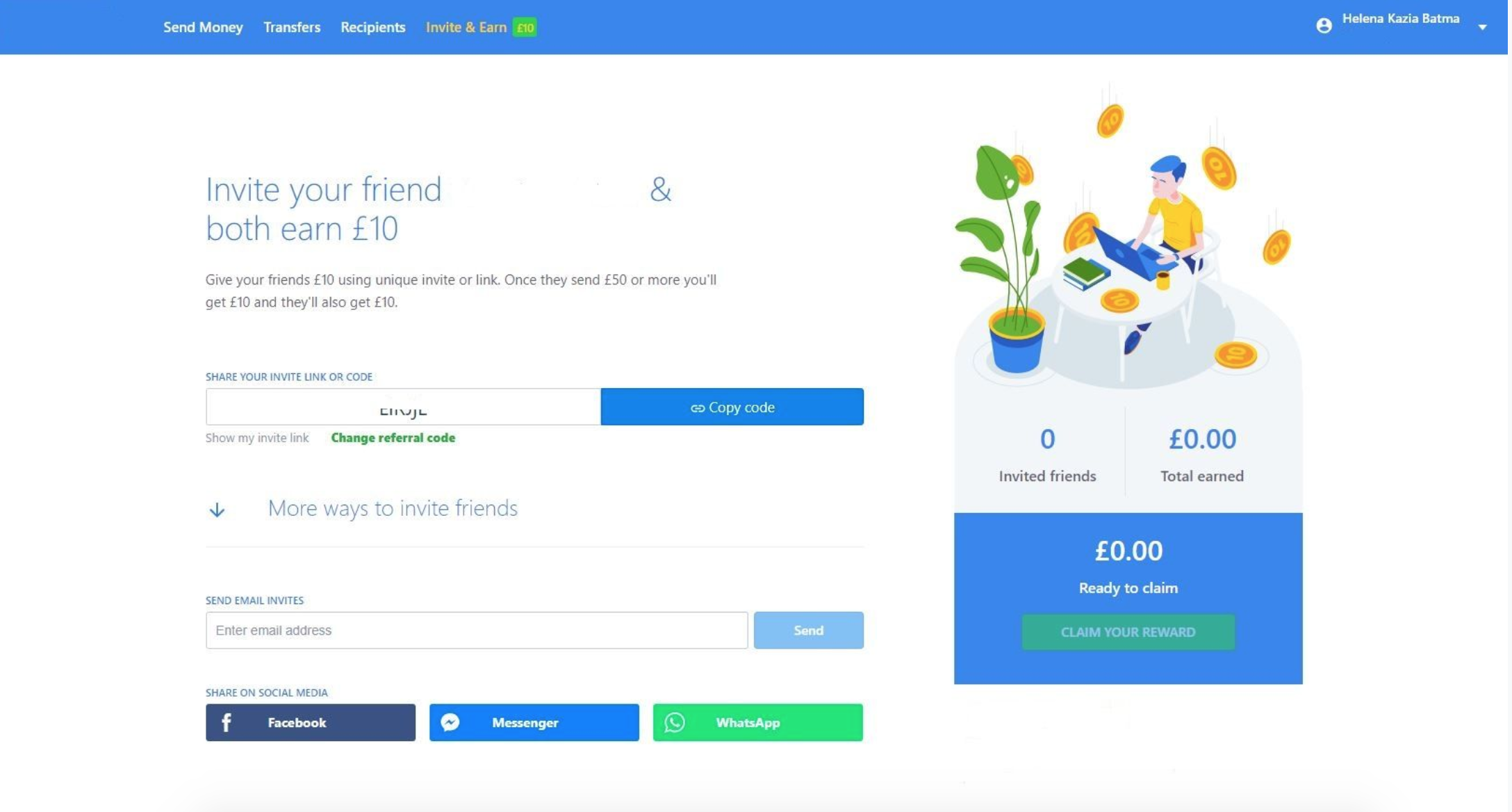

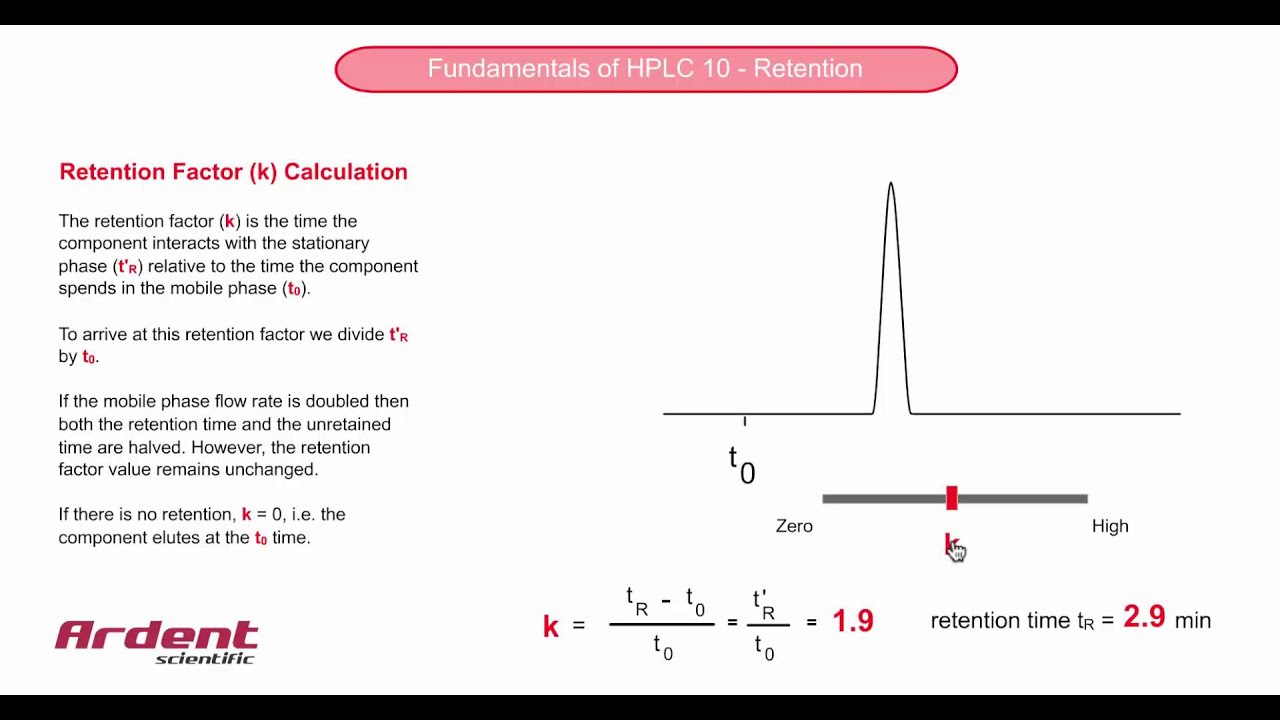

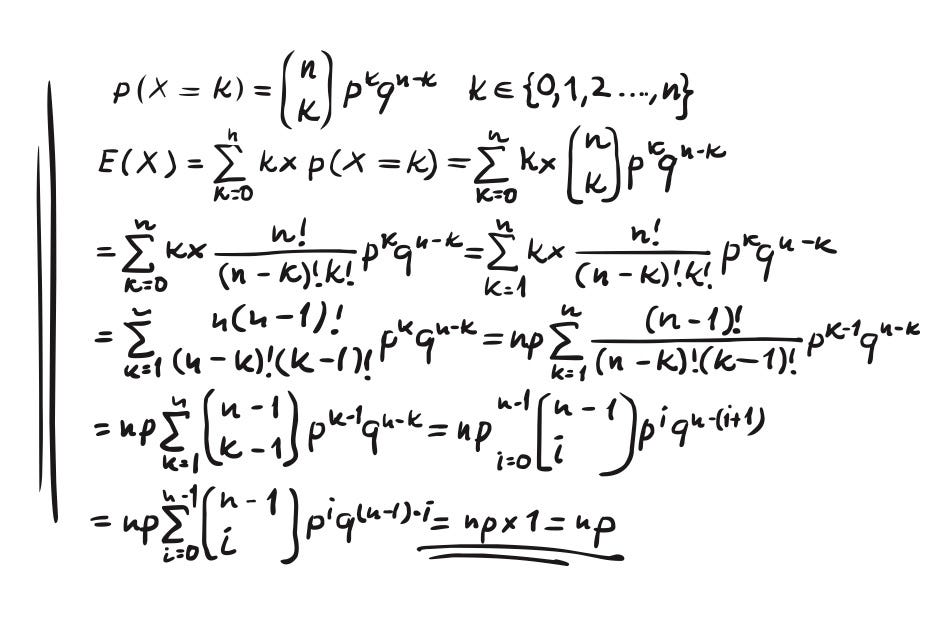

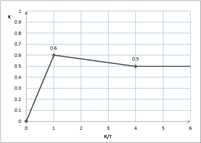

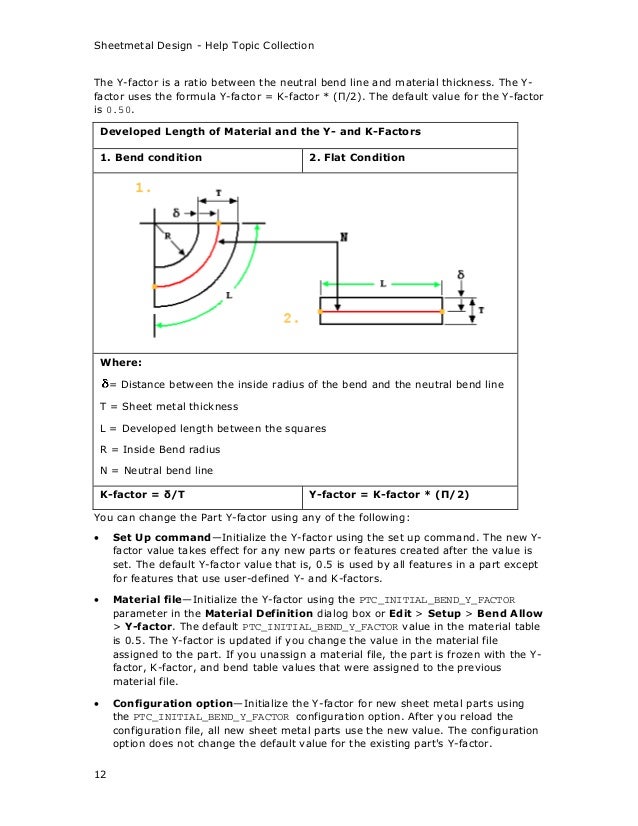

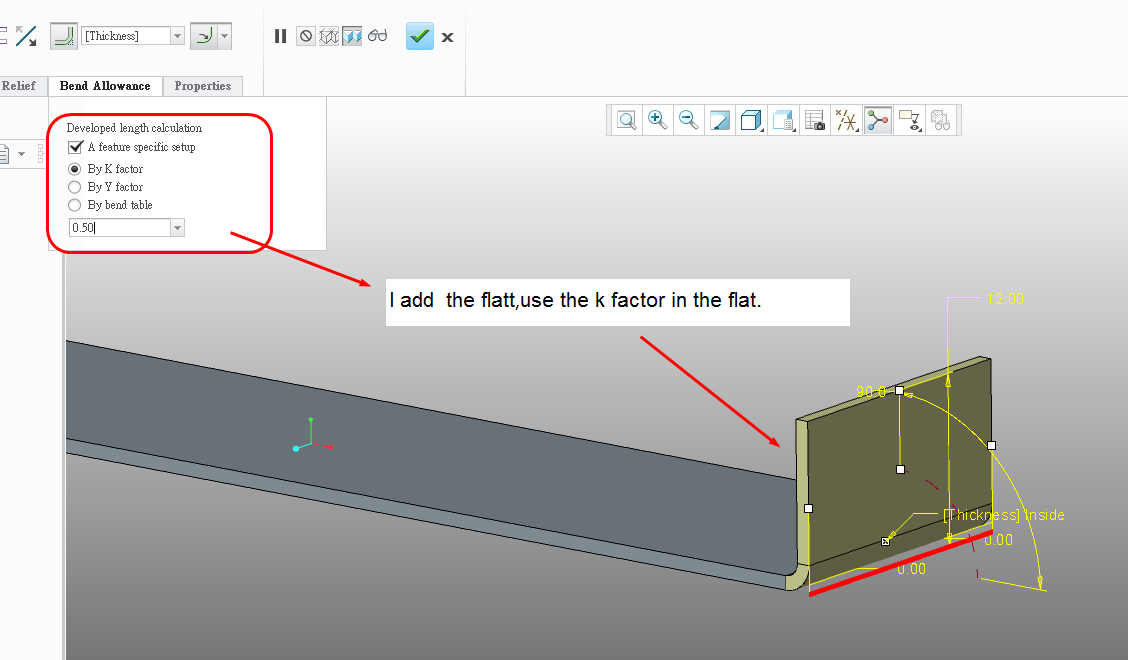

Still if you have any change in the method of forming type of material or the ratio of inside bend radius to material thickness you will have a different k factor value. Below the image shows how the top of the bend is compressed and the bottom is stretched. The k factor is the ratio of the neutral axis offset t and the material thickness mt.

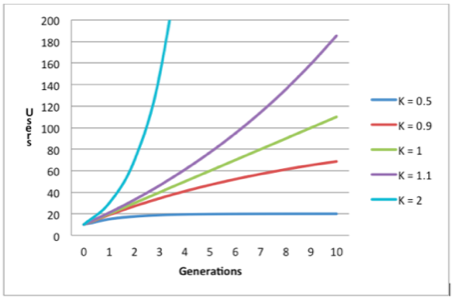

K value of k factor. Since the early days of the petroleum industry some physical properties of crude oil were used to define characterization factors for classification of crude oil with respect to hydrocarbon types 4 as shown in equation 8. K u o p o r w a t s o n t b 3 s g 15 0 c.

K factors calculated in metric units. The k factor is the most important and elusive variable of bending because it varies both as a function of the material and according to parameters such as angle and tooling. The k factor is defined as the ratio between the material thickness t and the neutral fibre axis t ie.

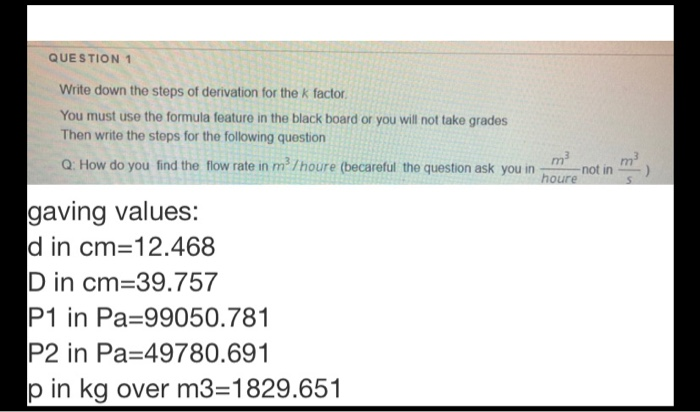

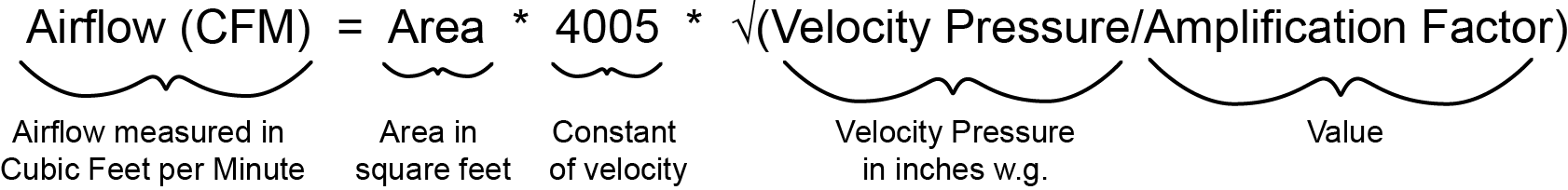

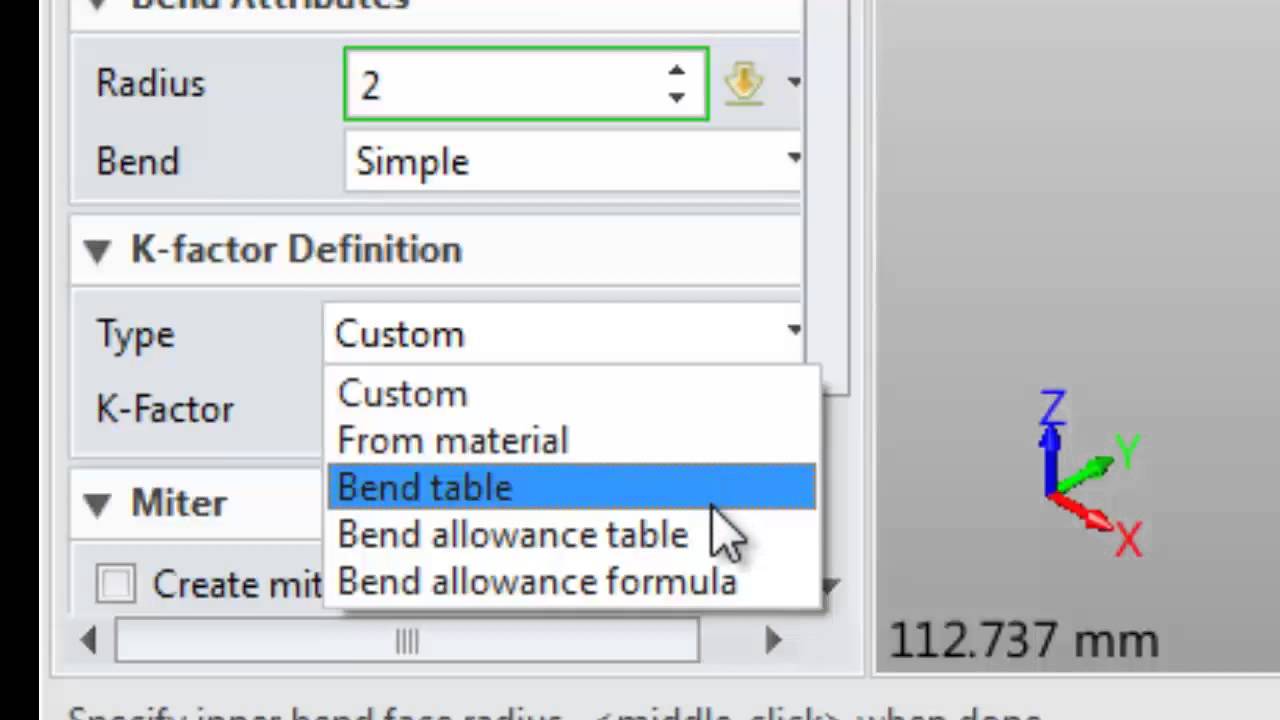

The flow rate of a nozzle is given by where q is the flow rate in litres per minute lm p is the pressure at the. The part of the material that bends. Input material thickness and and inner radius to get the data of k factor y factor neutral layer.

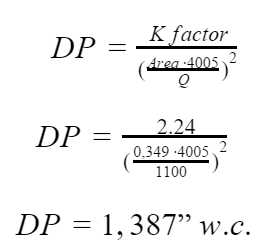

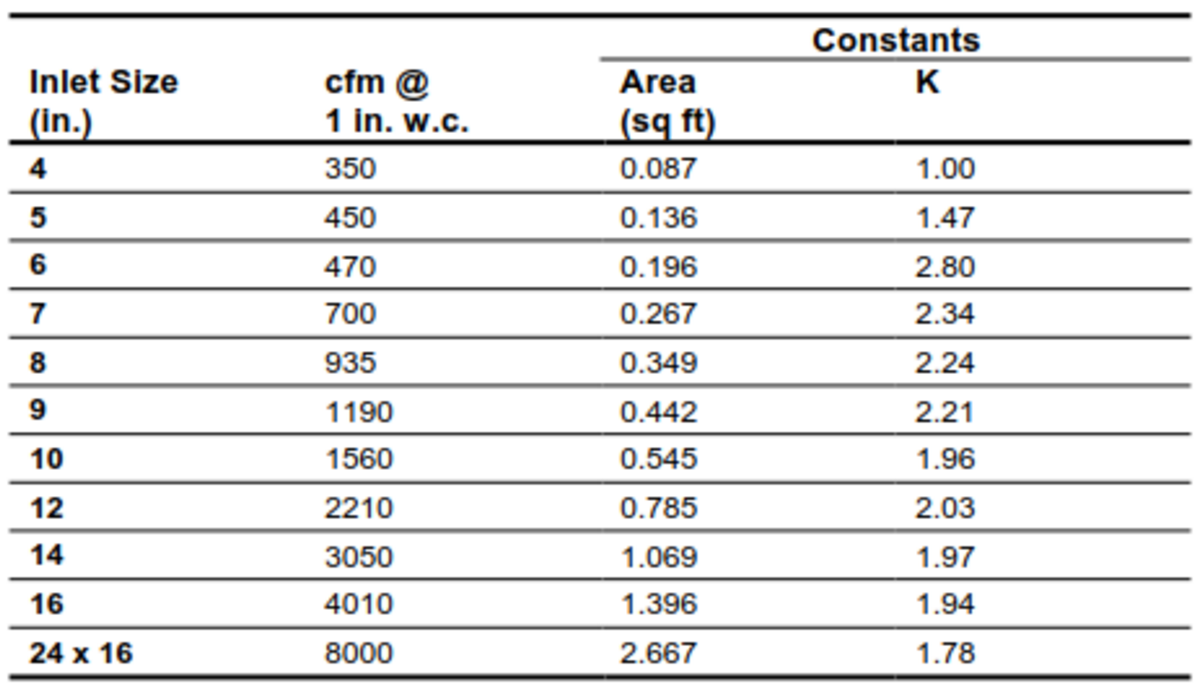

The k factor formula for fire protection. Spray nozzles can be fire sprinklers or water mist nozzles hose reel nozzles water monitors and deluge fire system nozzles. Flow meter k factor.

Therefore to calculate the k factor you can run an experiment at your factory. In fire protection engineering the k factor formula is used to calculate the discharge rate from a nozzle. Calculate k factor bend allowance and y factor for sheet metal bending.

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcsjs0idetji4r4dtsg3uaz53byb9 S6kyi Xynsgmpwmh N2qkr Usqp Cau

encrypted-tbn0.gstatic.com

Improving Cover And Management Factor C Factor Estimation Using Remote Sensing Approaches For Tropical Regions Sciencedirect

www.sciencedirect.com

0733-9445(2000)126:5(633).fp.png)