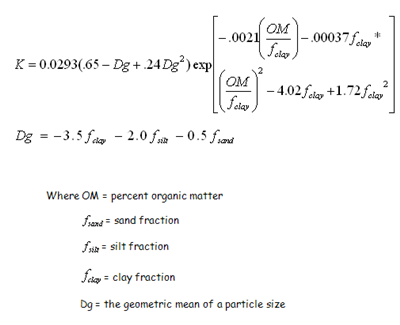

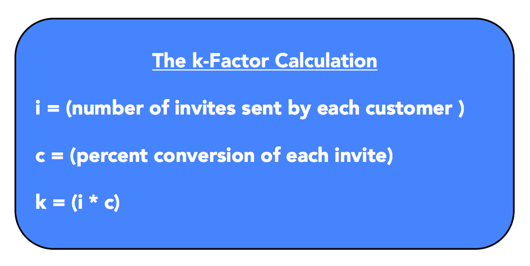

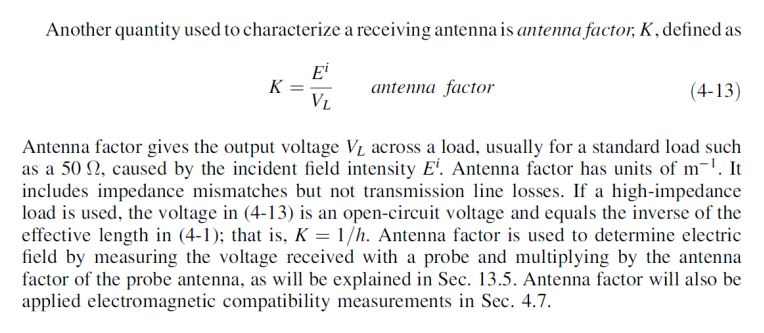

K Factor Calculator Formula

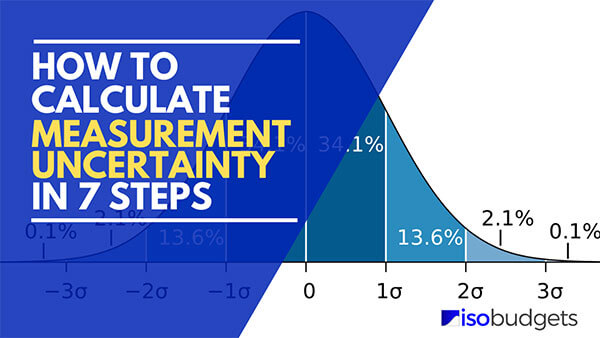

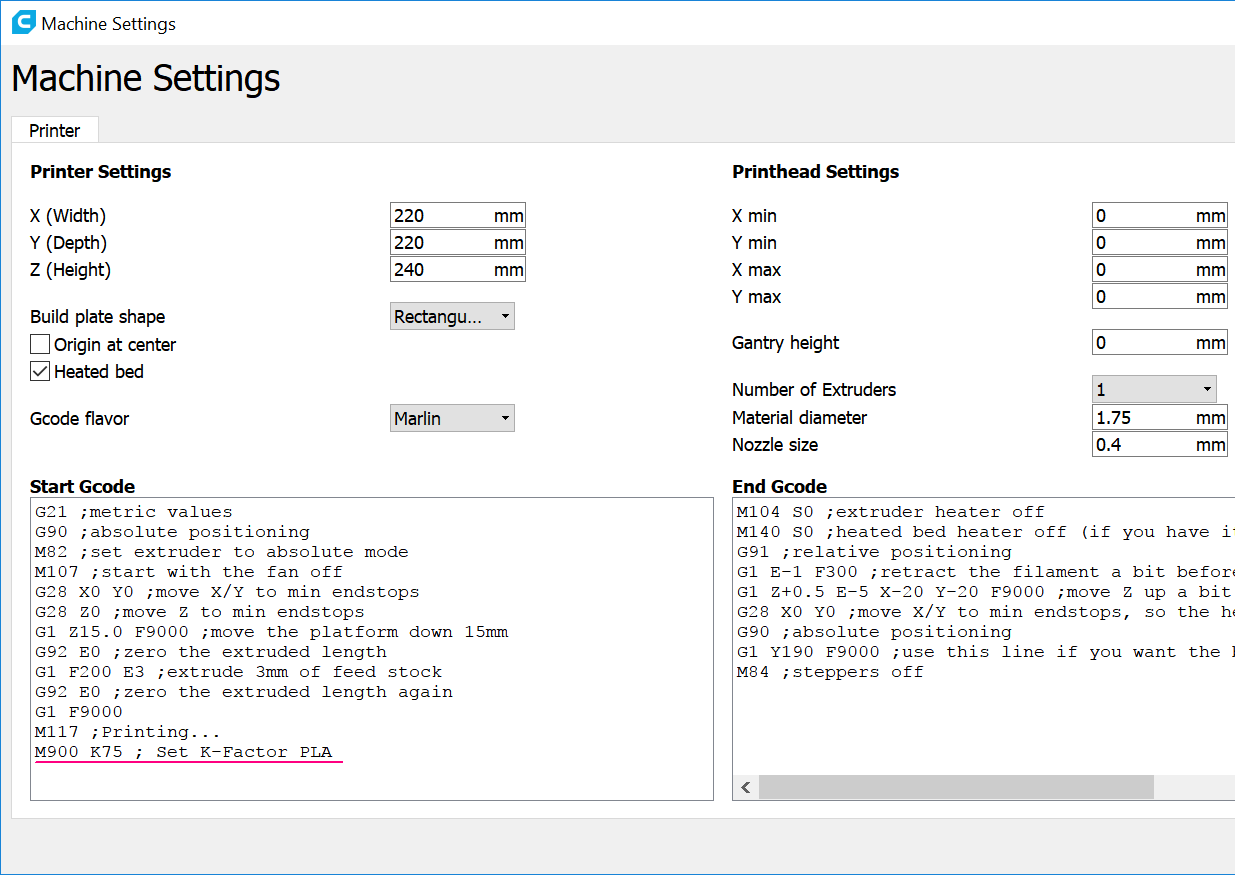

Typically the k factor is going to be between 0 and 5.

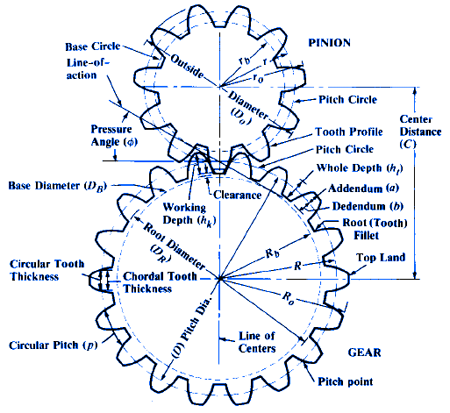

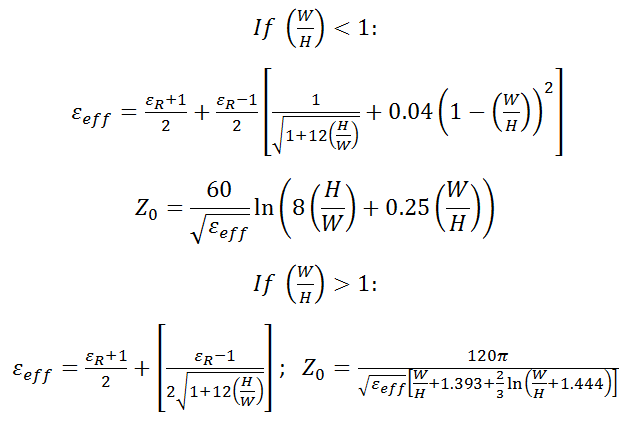

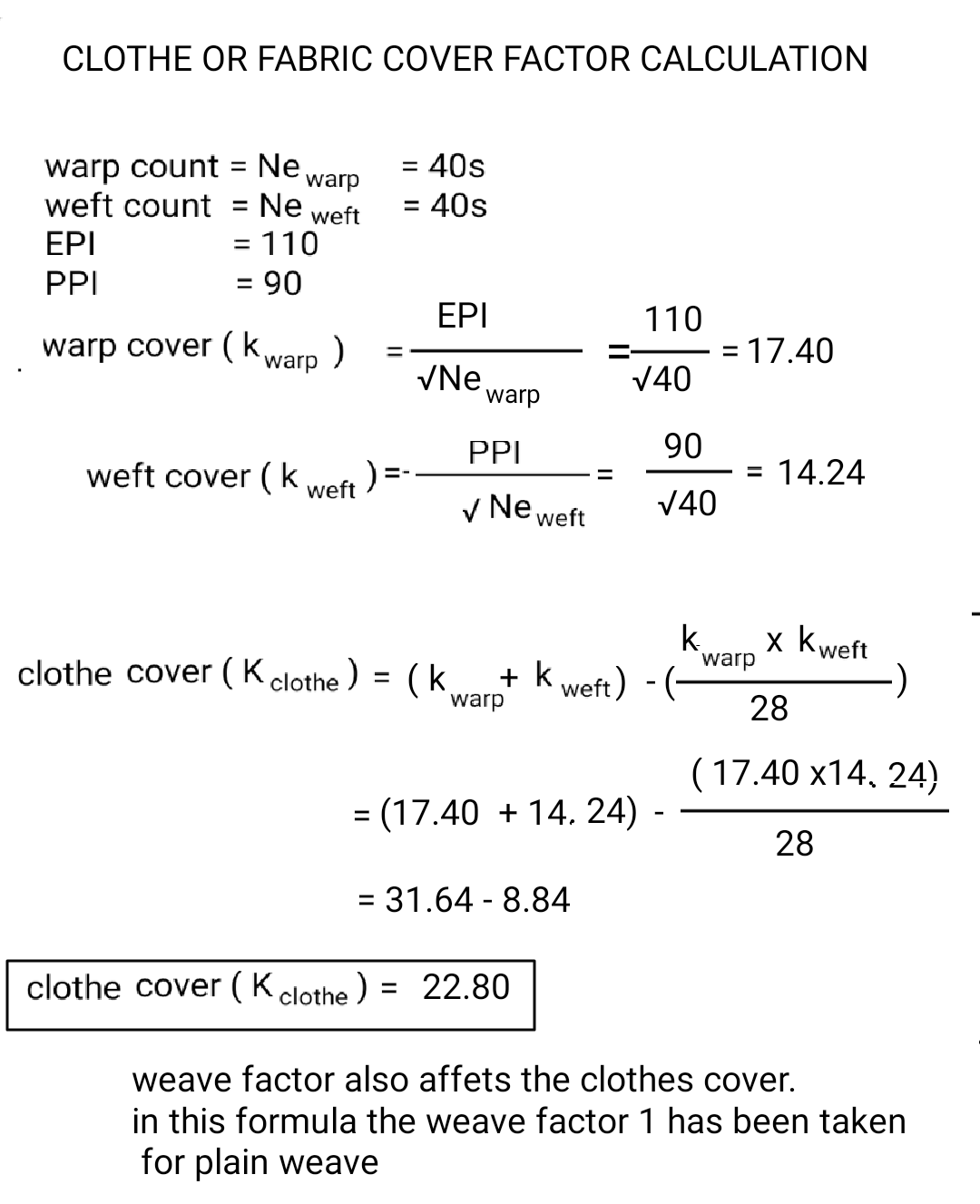

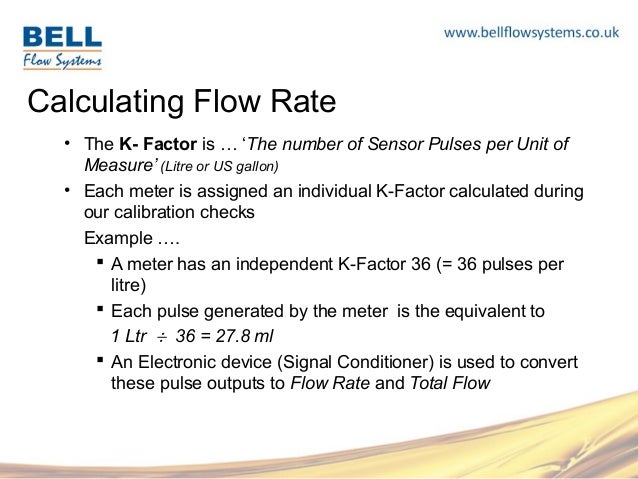

K factor calculator formula. Flow meter k factor. Cad tools use k factor to calculate sheet metal blank size. Die edge radius in.

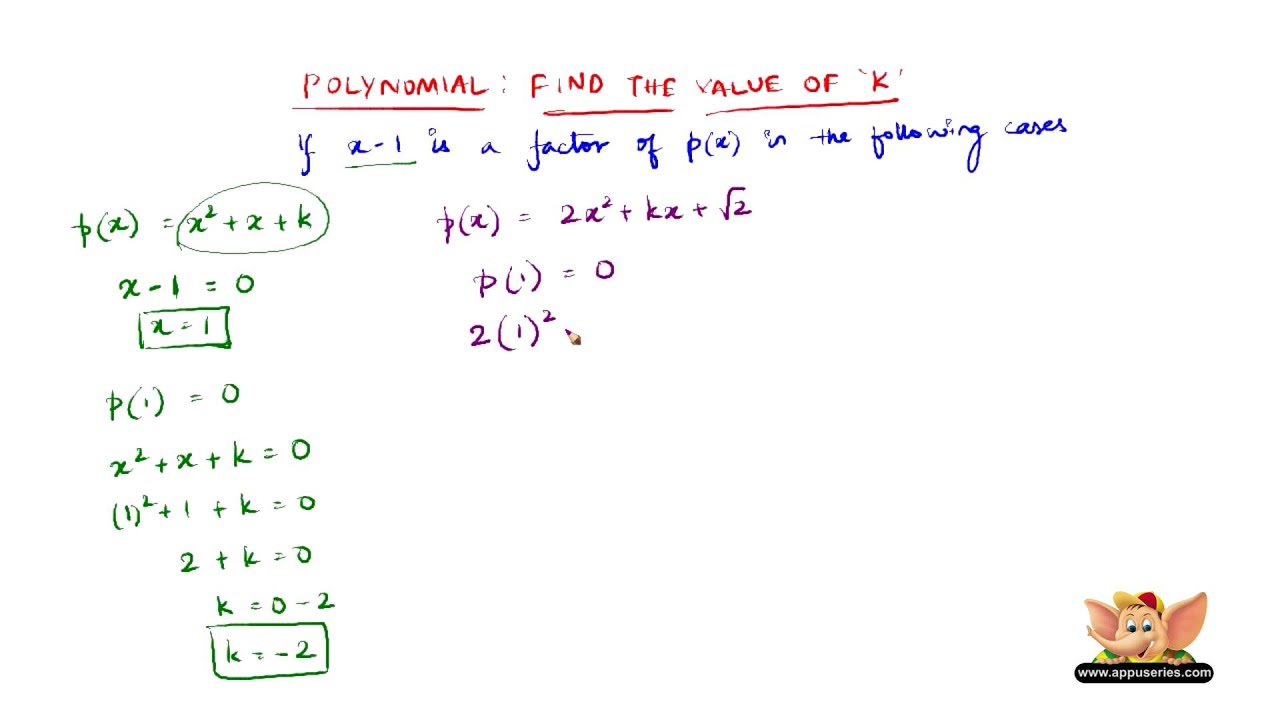

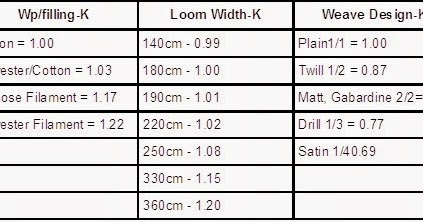

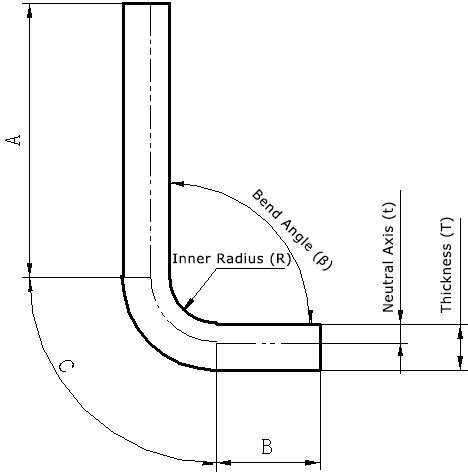

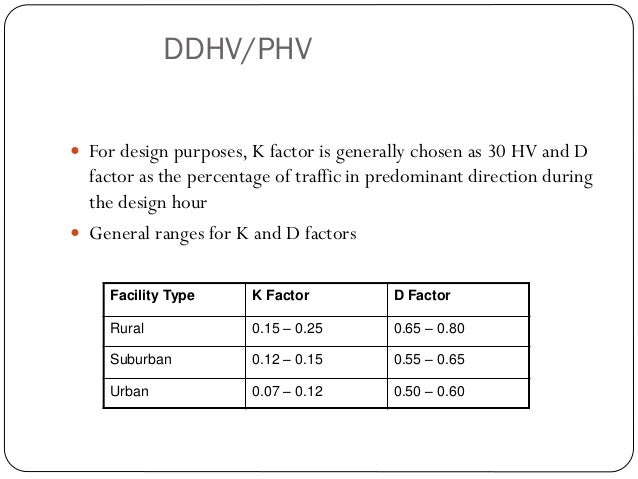

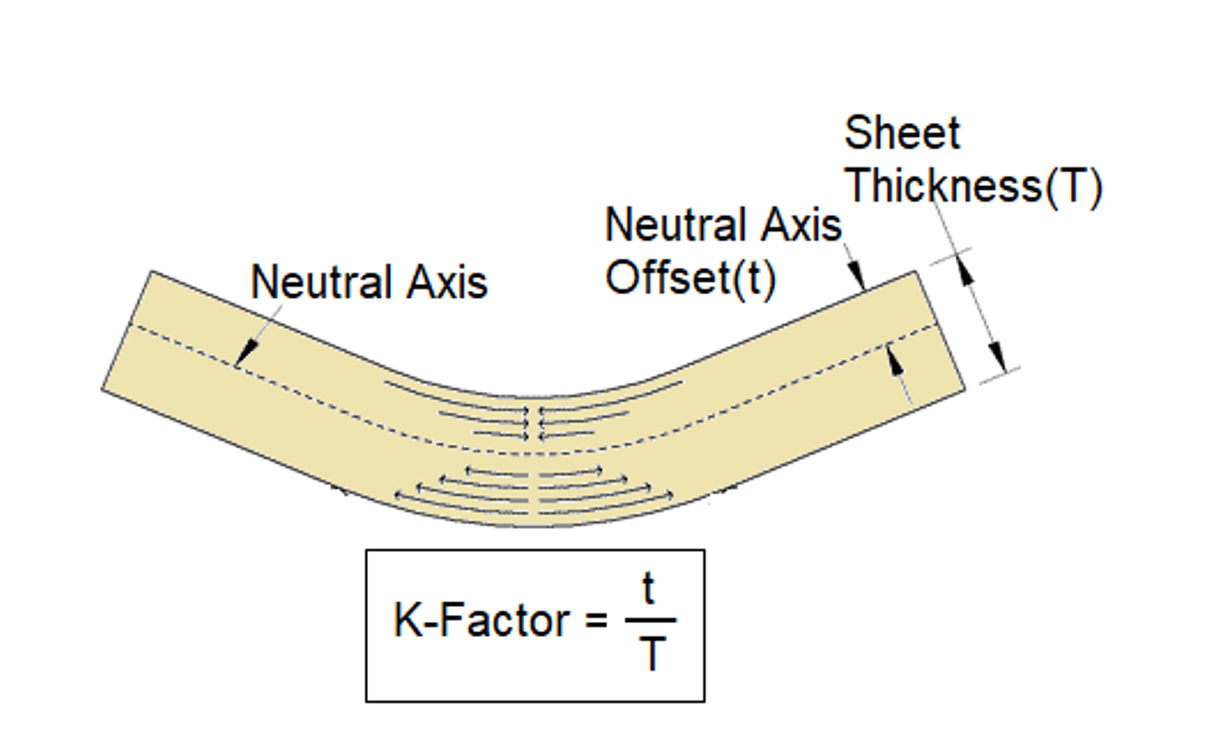

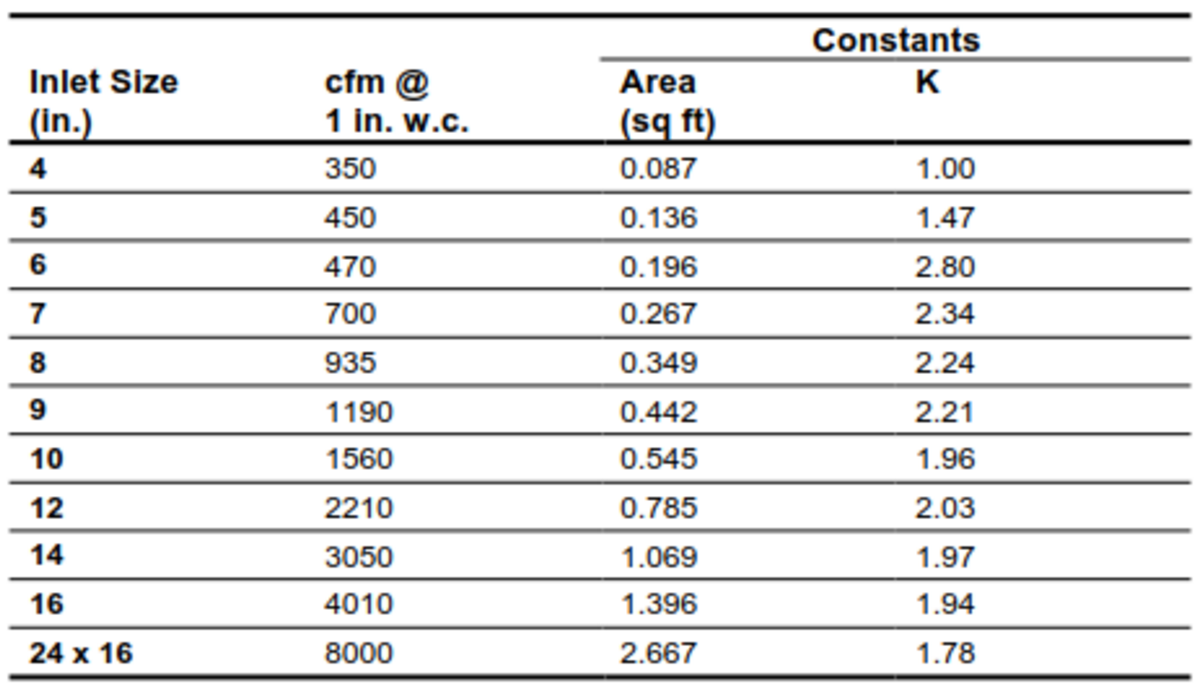

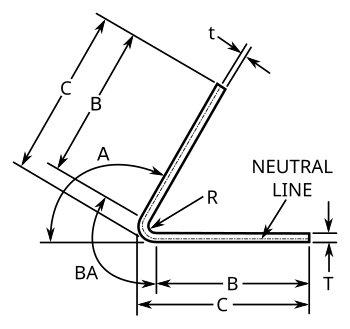

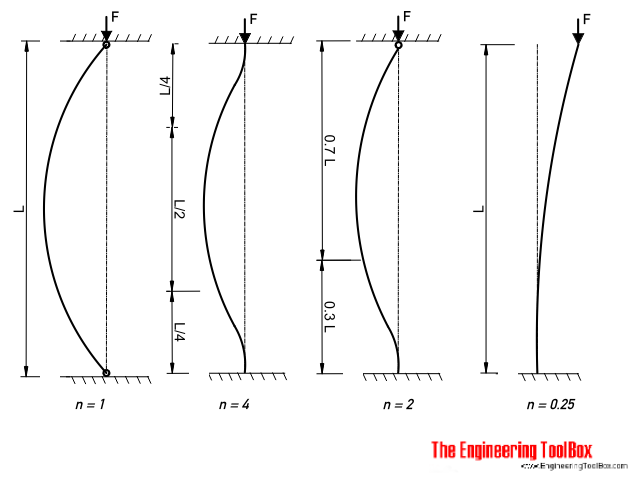

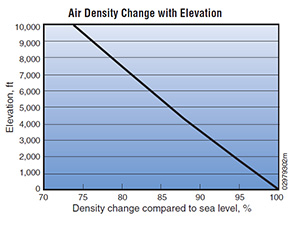

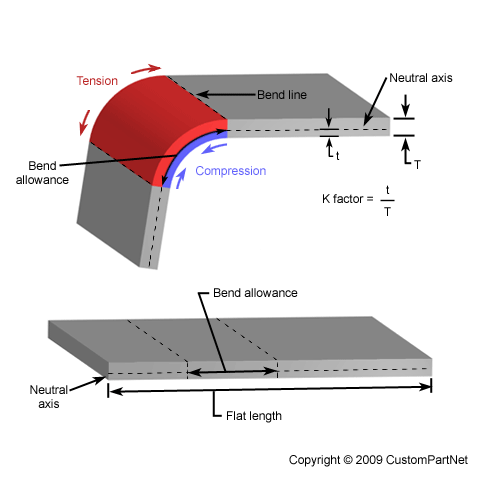

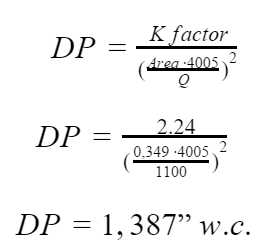

Indeed if we have an 8 inch vav box from the same manufacturer the maximum cfm is 1100 cfm. The k factor is defined as the ratio between the material thickness t and the neutral fibre axis t ie. Since the k factor is based on the property of the metal and its thickness there is no simple way to calculate it ahead of the first bend.

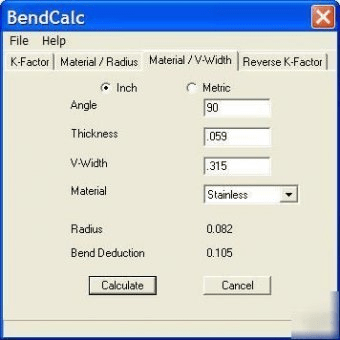

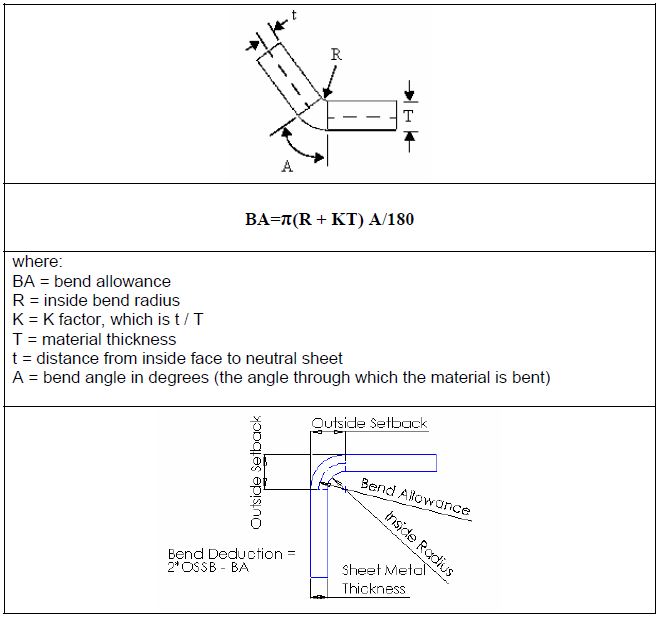

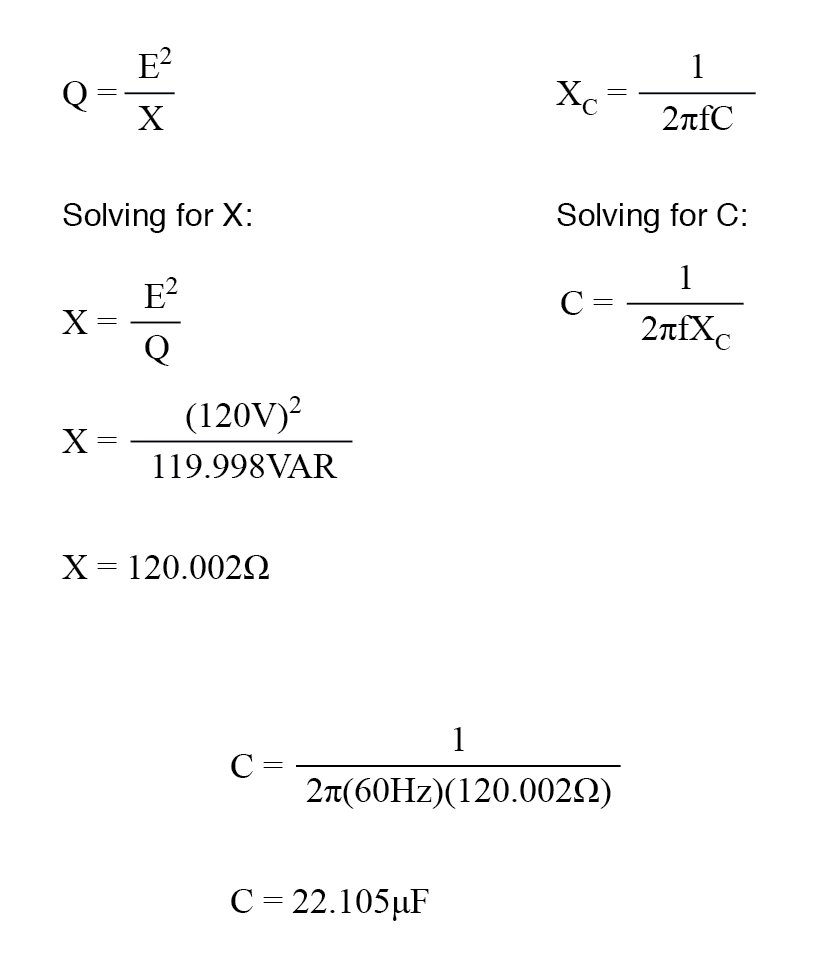

In order to find the k factor you will need to bend a sample piece and deduce the bend allowance. You can use this k factor calculator to calculate k factor using reverse engineering method. Calculate k factor bend allowance and y factor for sheet metal bending.

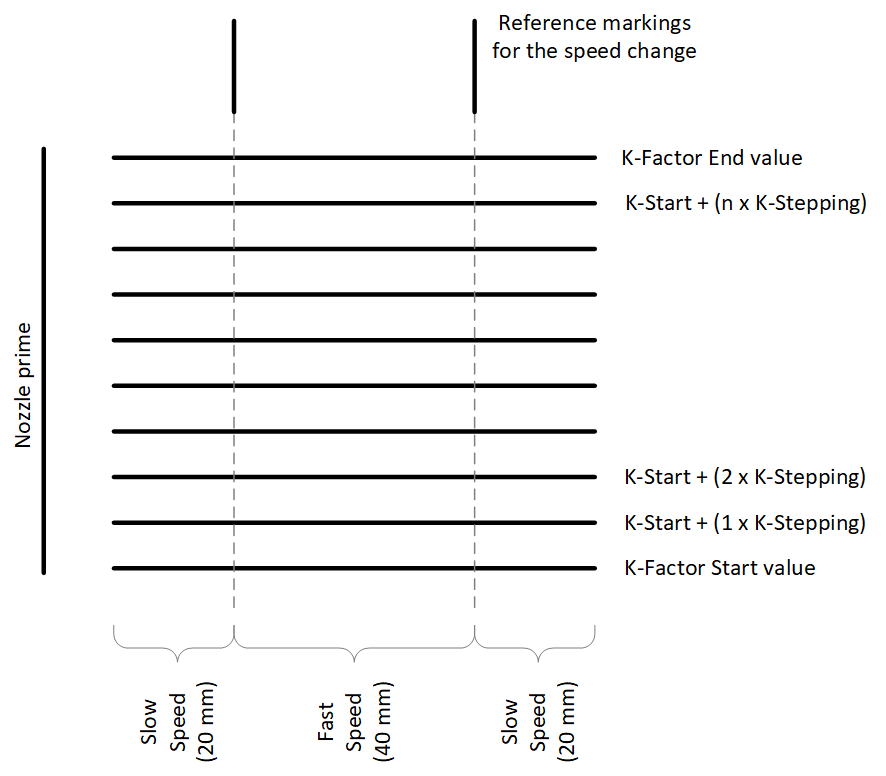

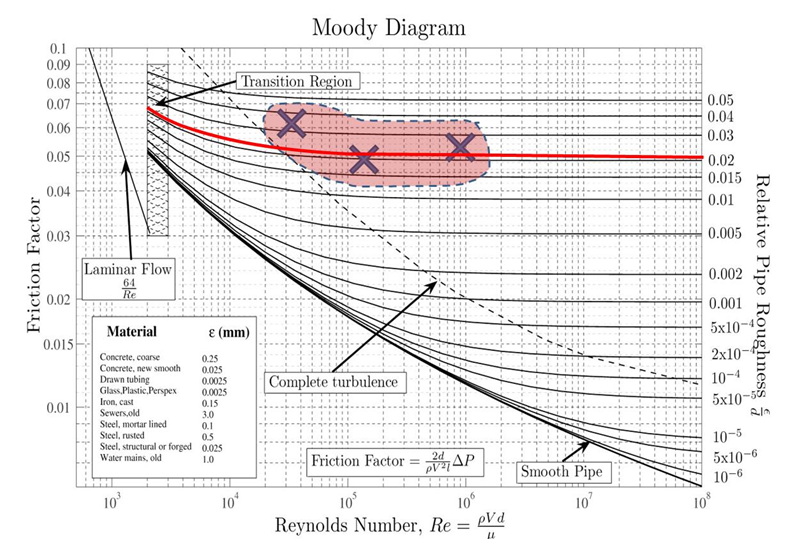

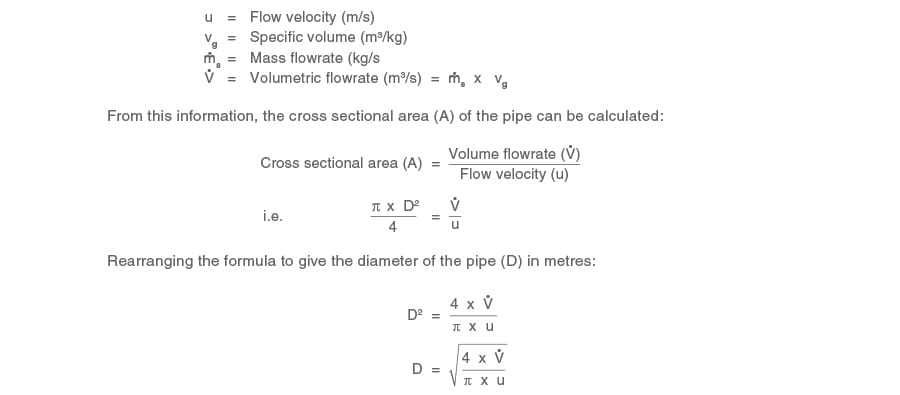

With the formula we can calculate the maximum velocity pressure we will have to measure. The k factor is the most important and elusive variable of bending because it varies both as a function of the material and according to parameters such as angle and tooling. To calculate the neutral axis distance from the inner face t we can subtract inside bend radius from r.

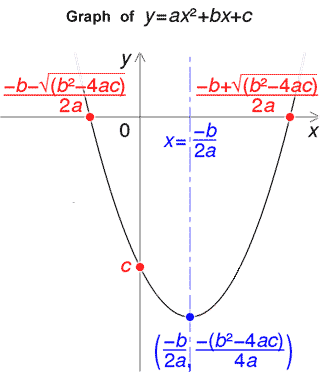

To calculate r which is the radius of the arc on the neutral axis we can use the following equation. The k factor depends on many factors including the material the type of bending operation. We suggest you also read this article on k factor and flat pattern calculations.

The online free fabrication calculator will help you calculate the k factor y factor bend allowance bend deduction flat size neutral axis arc length etc. The axial design of turbine flow meter is inherently linear within a known turndown range typically 151 based on velocity of the measured fluid. The part of the material that bends.

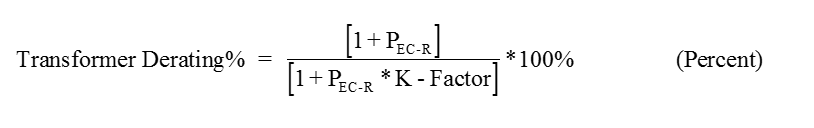

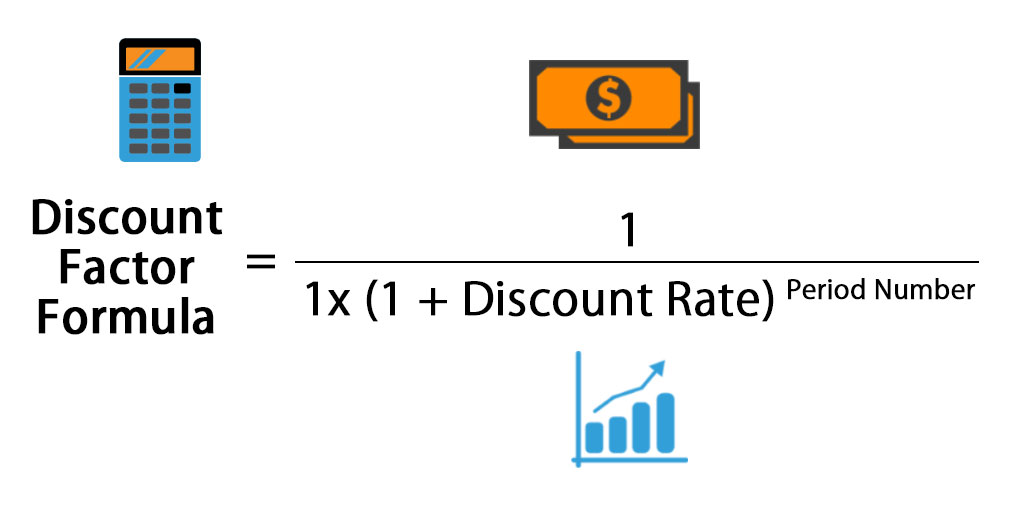

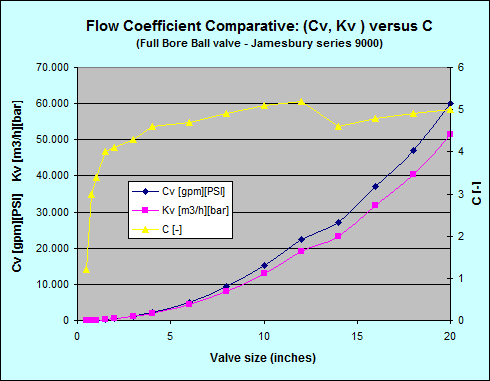

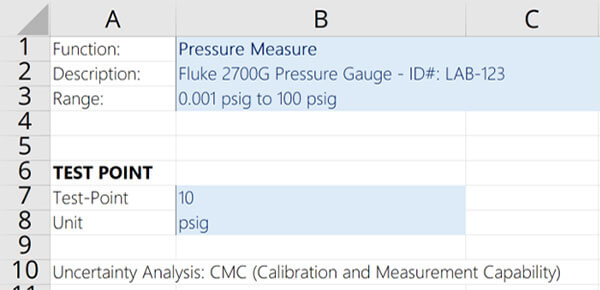

The k factor formula is the start of all hydraulic calculation for fire protection systems for both manual and computerized calculations. The k factor can help you choose the best range transducer for the pressure measurement. Ultimate tensile strength psi.

The device has unmatched capability of precise and repeatable k factor generation based on the turning of the balanced rotor and the subsequently generated frequency pulse signal via the magnetic coil assembly providing. The k factor formulation does not take the forming stresses into account but is simply a geometric calculation of the location of the neutral line after the forces are applied and is thus the roll up of all the unknown error factors for a given setup. K factor formula for fire sprinklers 44 0113 328 0350.

A is the bending angle in the above equation so.

Calculate K Factor Bend Allowance And Y Factor For Sheet Metal Bending Gasparini Industries

www.gasparini.com